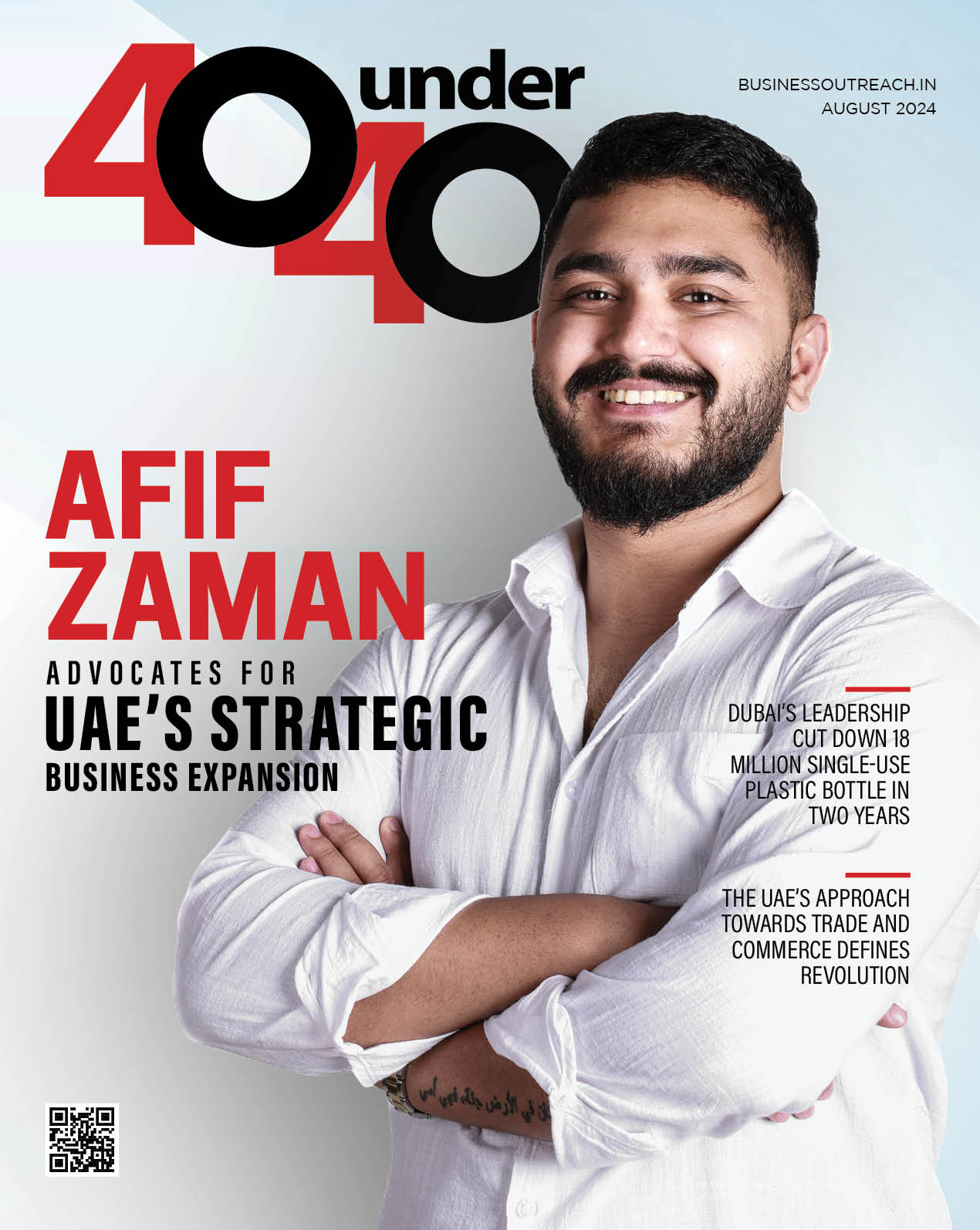

Expansion Supports UAE’s Operation 300bn and Economic Diversification

The subsidiary of the Ducab Group-Ducab Metals Business-announced on Tuesday a significant increase in its production capacity, saying it more than doubles from 55,000 tonnes per annum to 110,000 tpa annually. The company has also substantially raised its capacity for bare copper products and prepared itself for a surge in global demand for UAE-manufactured metals. As such, this strategic expansion is in line with the UAE’s greater economic diversification under the Operation 300bn industrial strategy, further cementing the country’s status for leading high-quality, innovative industrial manufacturing.

PC: Zawya

Ducab Metals Business Expansion Forum

This was announced during the ‘Ducab Metals Business Expansion Forum: Advancing Capacity, Driving Innovation’ organised in association with Middle East Economic Digest (MEED), gathering key players from industry, government, and academia to discuss the future of the UAE’s industrial sector and what needs to be done to achieve the ambitious targets of Operation 300bn.

Besides updates on the production capacity expansion plan of DMB, the forum underlined the company’s edge in continuous innovation and sustainability. DMB is pioneering a new development in green aluminium to reinforce its commitment to sustainable manufacturing practices.

Key Attendees and Statements

Among those who attended the forum were Ducab Group CEO Mohammed Almutawa and DMB CEO Mohamed Al Ahmedi, with representatives from the Ministry of Industry and Advanced Technology, Khalifa Economic Zones Abu Dhabi-KEZAD Group, and the Abu Dhabi Investment Office.

Ducab Group’s chief executive officer, Mohammed Almutawa, confirmed the firm’s commitment to developing industrial and production capabilities through strategic investments in line with the objectives of Operation 300bn. He said, “This expansion increases our ability to meet global demand, adds value to the ‘Made in the Emirates’ brand, and increases our international competitiveness, while driving sustainable business growth and building resilience in industry.

Mohamed Al Ahmedi, CEO of DMB, had reiterated the same by stating that the company was committed to fostering the UAE’s industrial sector. “Doubling our aluminium production and expanding our copper capabilities reflects our commitment to driving innovation and reinforcing our status as a major global producer,” said Al Ahmedi. He also said adopting advanced, sustainable technologies is of prime importance to maintain the lead for DMB in industrial and technological development.

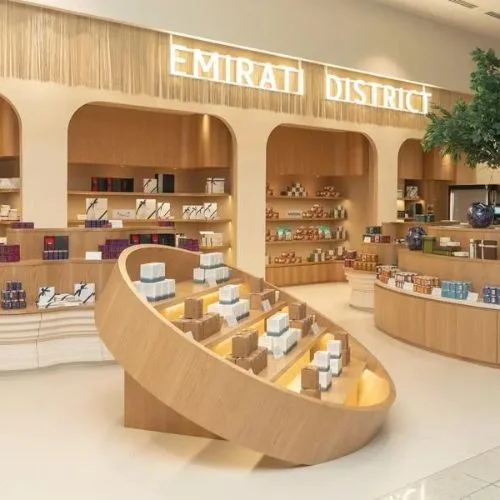

Expanded Facilities and Strategic Acquisitions

This added 51,015 square metres to its operations. What’s more, this enlargement further consolidates DMB’s position as one of the most important manufacturing centres within the said company, allowing it to better service an array of industries, including health and wellness, automotive, and packaging.

In addition to its physical expansion, DMB has also executed strategic acquisitions to help fuel its growth. Acquisition of GIC Magnet, a leading global supplier of paper-insulated aluminium strips, underlines DMB’s commitment to both innovation and diversification of its products. All these instances place the DMB in a strategic position to expand further its global reach and serve an increasingly diversified range of industries.

Supporting Non-Oil Trade and Global Investments

This expansion will be a step for DMB in supporting the UAE’s Industrial Strategy and the country’s non-oil trade, which is so instrumental to the economic diversification of the nation. The increase in production capacity and strategic acquisitions align with the drive by the UAE toward attracting more global investments into the country for its ambition as a leading hub for the industries of the future.

It is into this that further growth by DMB will mean increased effort in the adoption of advanced and sustainable technologies, hence driving the attainment of industrial and technological developments in the UAE. In fact, the expansion is another massive jump toward sealing the country’s leadership in high-quality, innovative industrial manufacturing.